Colour Swatches

This product is available in the following colours.

Disclaimer: Although every effort has been made to display the colour swatches shown as true, all monitors are not consistent in colour representation, the swatches therefore should be taken only as a guide!

Maintenance

Care of your new rigid letters

Congratulations, you have just bought ‘the best’. Impact Signs use ‘new generation’ materials for all of their fascia signs. Everything that we use is…

- UV stable (fade resistant).

- Waterproof.

- Rot proof

- Virtually maintenance free.

- All you have to do is clean with soapy water and a sponge as required. That’s it!

Lighting

Add Lighting and Get Noticed

Enhances any sign and gives higher visibility especially at night.

With an attractive curved profile housing a unique polished aluminium reflector, it is the answer for a constant run illumination of signs, fascias, pelmets and skirtings. Adjustable stand-off brackets allow accurate adjustment of light throw of signs up to 3000mm depth. The aluminium body is available in silver anodised and powder coated white finish. Sections can be butt-jointed with available adaptors.

Features & Benefits: Powder coated white or black as standard but can be to any RAL colour, waterproof, rot proof, maintenance free (tubes are easily changed).

DIY

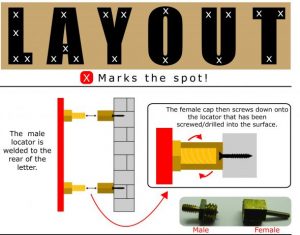

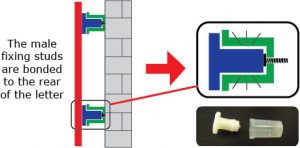

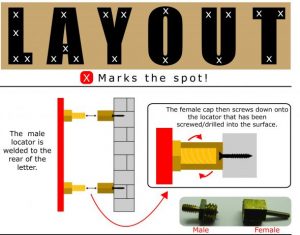

- When we supply you with individual cut letters, we also supply a “Fixing Layout” made from craft paper, showing the drawn round letters (in a layout) with the “Fixing” points marked with an “X”, this is indicated at the top of the page, - X marks the spot!

- You place the “Layout” at the required position on the fascia and drill where the “X’s” are!

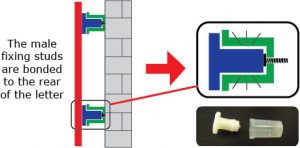

- The female cap is then screwed into the fascia (Giving the screw half a turn back to allow the cup to swivel and screw down)

- Push the letter into the cups until and audible click is heard if using nylon fittings, for metal letters using brass fixings screw down the cap until it is tight.

It’s as easy as that!

Note: for metal letters, we would use brass screw type locators, exactly the same fixing method as above but instead of ‘snapping’ in place you simply screw the nut to to the thread on the letter.

Testimonials

Click here to read impartial, anonymous reviews vetted by THE Trading Standards

Click here to read impartial, anonymous reviews vetted by THE Trading Standards

Click here

Click here