Flat Cut Acrylic Letters

Superior high gloss sheen. 10 year manufacturers guarantee. Will not rust, rot or corrode. Superior UV resistance. Slightly cheaper than aluminium letters. Any typestyle or logo can be recreated. They can be flush mounted or ‘stood off’ from the wall (approx ¾”). Rear fixings are hidden, s

Why Choose Flat Cut Perspex Letters?

With a 10 year manufacturer’s warranty against colour fade and cracking, you can be reassured that your Perspex letters will look impressive for many years to come.

Perspex comes in a wide range of colour options, each offering a high gloss finish. It is a highly durable product that we can cut in any typestyle or logo. Perspex letters are ideal for a contemporary look on and in retail outlets, offices, industrial units and entertainment facilities.

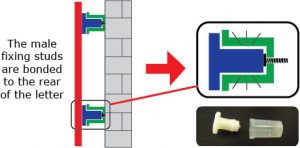

As with all of our individual lettering, Flat cut Perspex is attached using rear fixings, which are hidden from view; there will be no screws to distract from the smooth sheen and rich colour. We offer a full installation service for all lettering.

Perspex lettering can be used for internal and external applications. It is weather proof and remains in pristine condition without any need for maintenance. It can be flush mounted or raised ¾ inch/ 20mm from the wall.

If you have a more unusual idea for flat cut Perspex, come and speak to Impact Signs; we love a challenge!

(inc. VAT)

Process

It's as easy as 123

| Let’s get started with your Ideas, the more detail you provide the better! |

| We’ll email or phone you to talk it through, give advice and provide a quote. |

| It’s then over to us to create and amend artwork and you to pay the deposit. |

| If you provide the artwork, we’ll pre-flight check it for you and you pay the deposit |

| With your approval, we’ll get cracking on with the production. |

| We’ll soon be back in touch to arrange fitting/delivery/collection.

We will never proceed with production until you are entirely happy with the artwork and will always provide a proof (unless the artwork is supplied by you). |

Colour Swatches

This product is available in the following colours.

Disclaimer:

Disclaimer: Although every effort has been made to display the colour swatches shown as true, all monitors are not consistent in colour representation, the swatches therefore should be taken only as a guide!

Maintenance

Care of your new rigid letters

Congratulations, you have just bought ‘the best’. Impact Signs use ‘new generation’ materials for all of their fascia signs. Everything that we use is…

- UV stable (fade resistant).

- Waterproof.

- Rot proof

- Virtually maintenance free.

- All you have to do is clean with soapy water and a sponge as required. That’s it!

Accessories (Lights)

Add Lighting and Get Noticed

Enhances any sign and gives higher visibility especially at night.

With an attractive curved profile housing a unique polished aluminium reflector, it is the answer for a constant run illumination of signs, fascias, pelmets and skirtings. Adjustable stand-off brackets allow accurate adjustment of light throw of signs up to 3000mm depth. The aluminium body is available in silver anodised and powder coated white finish. Sections can be butt-jointed with available adaptors.

Features & Benefits: Powder coated white or black as standard but can be to any RAL colour, waterproof, rot proof, maintenance free (tubes are easily changed).

Nylon Locator Sizes

Impact Nylon Locators Sizes

DIY

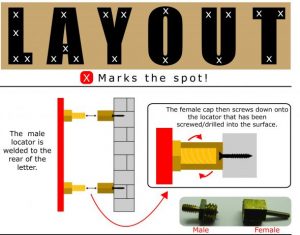

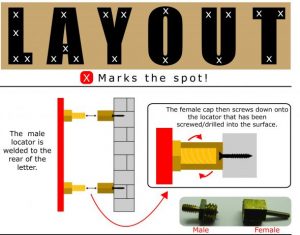

- When we supply you with individual cut letters, we also supply a “Fixing Layout” made from craft paper, showing the drawn round letters (in a layout) with the “Fixing” points marked with an “X”, this is indicated at the top of the page, - X marks the spot!

- You place the “Layout” at the required position on the fascia and drill where the “X’s” are!

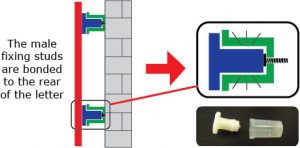

- The female cap is then screwed into the fascia (Giving the screw half a turn back to allow the cup to swivel and screw down)

- Push the letter into the cups until and audible click is heard if using nylon fittings, for metal letters using brass fixings screw down the cap until it is tight.

It’s as easy as that!

Note: for metal letters, we would use brass screw type locators, exactly the same fixing method as above but instead of ‘snapping’ in place you simply screw the nut to to the thread on the letter.

Video

https://youtu.be/4D0vT-lJoB4

https://youtu.be/olzae2DECAA

Testimonials

Click here

Click here to read impartial, anonymous reviews vetted by THE Trading Standards

Click here

Click here