Aluminium: Control Panels

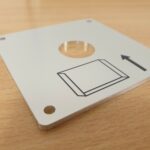

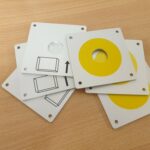

Our aluminium control panels are lightweight, strong, and corrosion-resistant, ensuring durability. Their good electrical conductivity enhances performance, and the material is suitable for customisation through our state-of-the-art engraving techniques. The sleek appearance adds aesthetic value,

Aluminium Control Panels

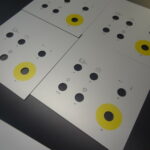

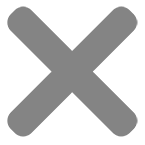

We specialise in manufacturing high-quality anodised aluminium control panels with a focus on functionality and durability. Bespoke precision engineering and custom sub-surface printing make our control panels ideal for various manufacturing needs.

Our control panels are purpose-built for use in demanding conditions. They are engineered to withstand the test of time, requiring minimal maintenance. Aluminium is inherently resistant to corrosion, and enhanced by the anodisation process, our panels maintain their appearance even in challenging environments, making them a reliable and durable investment.

Known for their long lifespan, our panels can endure extreme temperatures, weathering, chemicals, acids, oil, sea salt corrosion, thermal shock, and grease. Using a superior sub-surface printing technique, we ensure that the ink forms an enduring connection with the aluminium, resulting in a permanent and consistently legible bond. This exceptional quality not only guarantees resilience against various environmental challenges, but also safeguards from potential damage, preserving visual clarity for the long term.

Engineered for indoor or outdoor use, our control panels are versatile for use across various industries, such as the aerospace or food sectors. Drilled with bespoke, precision-milled apertures for switches, they offer seamless and efficient operation for a wide variety of applications from intercom panels to rack panel facias. We offer customisation options to meet your specific industrial, technological, or equipment needs.

Why choose anodised aluminium control panels?

- High-quality and precision engineering

- Customisable for specific needs

- Used across a wide range of applications and industries

- Resistant to harsh conditions

- Low maintenance requirements

- Long-lasting legibility

- Professional appearance

- Extended lifespan and reliability

(inc. VAT)

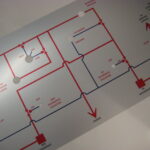

Process

It's as easy as 123

| Let’s get started with your Ideas, the more detail you provide the better! | |

| We’ll email or phone you to talk it through, give advice and provide a quote. | |

| It’s then over to us to create and amend artwork and you to pay the deposit. | |

| If you provide the artwork, we’ll pre-flight check it for you and you pay the deposit | |

| With your approval, we’ll get cracking on with the production. | |

| We’ll soon be back in touch to arrange fitting/delivery/collection. We will never proceed with production until you are entirely happy with the artwork and will always provide a proof (unless the artwork is supplied by you). |

Colour Swatches

This product can be printed in any colour, but the background will always be silver, not white. Disclaimer: Although every effort has been made to display the colour swatches shown as true, all monitors are not consistent in colour representation, the swatches therefore should be taken only as a guide! Disclaimer: Although every effort has been made to display the colour swatches shown as true, all monitors are not consistent in colour representation, the swatches therefore should be taken only as a guide!Tech Spec

Anodised Aluminium Control Panels

| Abrasion Resistance | No pronounced image loss, degradation or reduced readability after 7,000 cycles on an abrading wheel. |

| Acid Corrosion | No deterioration or image degradation after 24 hours in 3% nitric acid. |

| Heat Resistance | No legibility loss or degradation when subjected to 1,000°F. |

| Salt Spray Corrosion | No deleterious effect after a 720-hr salt spray (fog) test. 2,6 “Very Good” corrosion resistance after 113 days seawater exposure. |

| Accelerated Light and Weather Resistance | No pronounced deterioration of legibility after 400-hr carbon arc weatherometer exposure. ( ≈ 20+ year outdoor life) |

| Accelerated Oxygen Aging | No discoloration or fading after 96-hr/300 psi/ 70°C oxygen bomb aging |

| Stain Resistance | No black fading when plates are exposed to tincture of iodine. |

| Cleaning Resistance | No deleterious effects when tested with alkaline cleaners (MILC- 87937 or equivalent) for aircraft surfaces. |

| Low Temperature Resistance | No deleterious effect or image fade after 1 hour at -50°F. No impairment of legibility upon exposure at -67°F. |

| Organic Solvent Resistance | No softening, staining or noticeable fade after 24-hr exposure to: JP-4 fuel, Gasoline, Mineral Spirits, Methyl Ethyl Ketone, Turpentine, Turbine & Jet Fuel, Kerosene, Xylol, Acetone, Toluol, Heptane, Trichlorethylene, MIL-H-5606 Hydraulic Fluid and MIL-L-7808 Jet Engine Oil. |

| Fungus Resistance | Visual reading of “0” per ASTM-G21. |

| Thermal Shock | No deterioration after 3 cycles between -65°C and 125°C |

| Moisture Resistance | No deterioration after 10 humidity cycles per MIL-STD-202, method 106. |

Click here

Click here